Wayne Hill,

I completed my shipwright / boatbuilding apprenticeship, qualified as a yacht designer and hold an international commercial captains ticket. Uniquely experienced with over 100,000nm sailed and happily live aboard my sailing catamaran Mangrove Charlie since 1992. I live on the sea and love it.

These articular reflects my design philosophy and yacht construction knowledge at that time. I look back now and am proud to have been a pioneer of modern multihull design and construction.

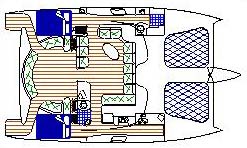

Special Accommodation Features

This exceptional interior design provides many cruising comforts and personal privacy areas making this sailing yacht very comfortable for extended ocean voyaging.

The spacious fully air-conditioned bridgedeck saloon, which has excellent all-round panoramic views through the saloon windows, standing or seated, comprises of three areas.

1. To starboard there is a dining area with seating for five providing comfortable dining around an amply sized servery / dining table, for the full party of owners and guests.

2. Centrally a large lounge features the ultra luxurious lounge style seating, which folds down to form an extra double bed, is capable of seating with ease a minimum of eleven persons around an amply sized coffee table.

3. While on the portside there is a business centre / navigation area facing forward with an all-round panoramic view through the saloon windows, actually enabling the navigator to visually check his navigation while sitting at his desk.

The layout features one ensuited master double stateroom in the port hull, one stateroom in the starboard hull with a separate toilet and shower, a spacious galley in the starboard hull, with the dining and lounge on the bridgedeck saloon.

The large comprehensively equipped open plan galley is located in the starboard hull and is designed for long term remote cruising, it measures 5 m long and 1.7 m wide is has solar powered domestic sized fridge and freezer and cubic metres of storage space and square metres of bench space, the galley features visual and practical access to a servery and dining table.

The spacious owners ensuited stateroom occupies the entire port hull, it is 7.5 m x 1.7m of pure luxury.

The stateroom features a queen size double berth which allows the use of standard linens and sheets for true live aboard comfort. Has nightstands, dressing table, a vanity desk, full length hanging space and sufficient lockers for all personal items.

The spacious ensuite features ; washer / dryer, wash basin, ample counter space and a large separate sitbath and shower, hot and cold pressure water, electric toilet, extractor fan, natural light and ventilation plus a full length mirror.

A guests cabin located starboard and aft, has a queen size double berth, nightstands, dressing table, full length hanging space and sufficient lockers for all personal items.

A guest / day visitors head with shower toilet and vanity is located between the galley and guest cabin.

The raised cockpit caters for outdoor entertaining / dining and allows easy access to the spacious forward deck and large swim decks aft. The twin two person Helmsman chairs with Navigation instruments cleverly designed into a raised console, provides excellent visibility and protection while at the same time offering maximum access to electronic instruments.

Large windows, port holes and hatches throughout this exceptional yacht provide a priceless view of exotic locations and allow ample daylight to shine in.

Standard Specifications

| Length overall | 12.5 m |

| Waterline length | 12.3 m |

| Sinkage rate | 150 kg/cm |

| Length to beam ratio of hulls | 13.2/1 |

| Length to draft ratio of hulls | 20.5/1 |

| Beam | 7.5 m |

| Draft Light Ship | 0.7 m |

| Underwing clearance | 0.8 m |

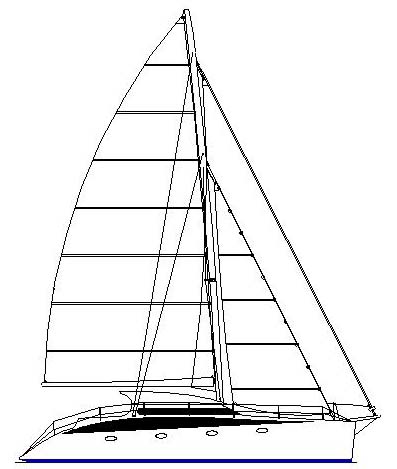

| Mast height | 15 m |

| Boom length | 6 m |

| Sail area mainsail | 50 sq m |

| Genoa | 50 sq m |

| Jib | 30 sq m |

| Staysail | 15 sq m |

| Spinnaker | 80 sq m |

| Fresh water capacity | 600 lt |

| Payload includes fuel, fresh water and personal equipment | 2000 kg |

| Engines twin diesels | 27 hp |

| Fuel capacity | 150 lt |

| Range | 500 NM |

| Continuous cruising speed | 8 knots |

| Berths - one ensuited double stateroom plus one double cabin plus one double bed or two singles. |

6 |

Construction

ISO polyester laminating resin / rigid closed cell PVC foam / resin infused multi axial fibreglass, finished with a quality durable polyurethane paint.

Special Hull Design Features

- Unique specially designed inboard flare in the hull.

- An easily driven hull shape to achieve sparkling performance under sail or power.

- A cleverly designed hull shape to provide a gentle motion at sea or anchor.

- Sufficient displacement to support all the desired cruising equipment.

- The longitudinal volume distribution along the waterline, is designed to trim the bows up when the yacht is being pressed hard under sail.

- The hulls feature a high length to beam ratio, with high prismatic coefficient, and round-bilge hulls for minimum wetted surface area, resulting in a high payload, high average speed, low wave-making resistance, reduced pitching motion, and excellent rough water capabilities.

- Semi circular transoms, to ensure sparkling light wind sailing performance.

- Stylish aerodynamically designed deck for maximum sailing efficiency.

- Internal no taste water tanks with Easy Fill, built behind the dagger board case. This position is practical, as well as technically favorable, as it is situated on the centre of buoyancy of the yacht reducing the pitching motion, and making the yacht less sensitive to various tank levels and lowers centre of gravity.

- Unique deck beams to maximize yachts stiffness and maintain rig tension.

- Deep forefoot to prevent hull pounding to windward.

- This yacht is more stable fore and aft than sideways to reduce the chance of pitchpoling.

- Large buoyant ski shaped composite forebeam and bowsprit to increase the ultimate stability.

Special Design Features

Full standing headroom throughout including hull access and full sitting headroom over the beds.

Electronic self tailing mooring rope winches forward for mooring lines ensuring easy docking.

The cockpit and helm position are covered by a solid canopy with sliding sun roof over the helm position for sail viewing and to improve crew comfort levels in adverse conditions.

Both sails and both bows and sterns can be viewed from the helm position for comfortable sailing and easy manoeuvring.

The raised cockpit provides panoramic vision over the saloon and allows a cool breeze to flow into the cockpit.

A specially designed gunwale moulding is fitted to protect the topsides and stop water stains on the topsides.

Below deck mounted electric anchor winch with self launching bow roller and stainless steel anchor chain.

No bolt heads on stainless steel chainplates or deck fittings and no internal nuts, stylish.

Stylish raked stainless steel stanchions moulded to deck.

External fuel tanks under cockpit sole for easy filling and cleaning.

Swim deck for easy access from water dinghy or dock.

Hull cupboards at bench height - 400mm to allow Max. Floor space.

The tender is stored clear of the waves on davits incorporating solar panels and VHF aerials.

Special Safety Features

Built in buoyancy to support the yacht if holed or capsized.

Forward foam bumperbar for collision protection.

Forward and aft collision bulkheads.

Capsize escape hatches in each hull.

Each cabin has two means of escape in emergencies.

Special Construction Features

Hull laminates in accordance with Australian Standards.

This yacht features a fully engineered composite beam structure.

Constructed with ISO polyester laminating resin / rigid closed cell PVC foam / resin infused multi axial fibreglass, finished with a quality durable polyurethane paint.

Hull below waterline epoxy resin / fibreglass coated to prevent osmosis.

The hull below waterline is coated with copper impregnated epoxy resin for extremely durable permanent antifouling.

All fibreglass fibres are prestretched and run the full length of the hull, without joints to ensure maximum strength and stiffness.

A longitudinal vertical beam, on the centreline under the cabin sole, provides a very strong beam for spreading the main beam loads and stiffens the hull for beaching or grounding.

Sufficient fibreglass to ensure a long service life of the yacht

Special Mast and Sail Features

A cleverly designed fully battened mainsail leach which is parallel to the mast on the lower panels, assists reefing and lowers the centre of effort.

A large deep hollow U shaped boom, with lazy jacks that become the boom toping lift when the halyard is released, catch the mainsail when reefing and lowering the mainsail, which makes short handed reefing easy and safe.

Low aspect ratio raked mast with an efficient easily handled cutter rig, lowers the centre of gravity to reduce pitching and increase stability.

Roller furling genoa on a bowsprit for maximum light wind and reaching performance.

Fully battened, non flogging, self tacking Staysail stored on deck.

All the genoa and jib sheets are led back to the cockpit.

The main halyard and reefing lines are led aft to the helmsmen Jib and spinnaker halyards are at the mast.

The mainsail and jib both use radial tracks for ease of control with minimum crew.

The spinnaker has a sock to help reduce crew fatigue.

Rudder and Daggerboard Features

Efficient balanced rudders for responsive maneuvering under helm or autopilot.

Unique specially designed Stabilizing Rudder Foils which reduce pitching considerably and increases average speed.

A steering mechanism which turns the outboard rudder less than the inboard rudder when turning, this improves responsiveness and reduces rudder induced drag when steering in a sea way or undertaking high angle turns.

Special Stainless steel rudder shafts designed to stop the yacht when grounding at normal speeds and support the weight of the yacht when beached.

Special Engineering Features

The engines have been carefully located to reduce direct engine noise to the accommodation areas.

The engine room is fitted out with sound insulation to further reduce noise.

The exhaust outlets are located aft and outboard to minimise on board exhaust fumes.

Engine propulsion by efficient propeller shafts, with propellers that are completely protected by the hulls.

The propeller shafts are angled inboard 7 degrees to further enhance efficiency and manoeuvrability, this also allows easy propeller shaft removal past the rudder and enabling easy cleaning of the propellors from the dinghy.

The propellers are deep to prevent ventilation when motoring in rough conditions.

Adequate clearance between the propeller tips and the hull to minimise water hammer.

The propeller is mounted directly ahead of rudder for maximum maneuverability and protection.

Equipment

When designing and building a cruising multihull we ensure the structural yacht including the mast rigging and sails and the engine and propulsion systems, are robust, durable and reliable. This ensures you can venture to distant and remote locations in confidence. Personal luxury equipment may be installed to enhance your yachts comfort, below are some possibilities.

Equipment for Mangrove Charlie

General

Furniture, drawers, door frames, cupboard doors, head liner, bulkheads, heads, are all moulded GRP then polyurethane painted to suit your colour system.

Floor Coverings; Hull and Saloon floors Loop pile carpet to your specifications.

Galley and dinning room have laid cork tiles with a clear polyurethane coating.

Upholstery to your specifications.

Galley

1x large stainless steel sink and drainboard with single mixer tap set.

3 Burner stainless steel gas stove with oven and grill.

1 x Fridge unit, complete with front opening door.

1 x Freezer unit, complete with front opening door.

800w microwave.

240v outlets.

Electronics

2 x Speed , depth and fishfinding instruments.

2 x VHF radios.

1 x 12volt stereo multi stack CD player AM/FM radio with amplifier and remote control supplying quality sound to two individually volume controlled speakers in each cabin, the cockpit and saloon areas.

Laptop computer with electronic charting, tide tables and Internet connection.

Global Positioning System.

12 volt DC to 240 volt AC 800 watt inverter.

Big screen stereo colour television with remote control.

High amperage battery charger.

300 watts of solar panels.

Electrical

All wiring to Australian Standards.

240v and 12v electrical switchboards with circuit breakers.

system air conditioning, for marina use only.

600 amp hour house batteries.

Two halogen lights per cabin, engine room, head, galley, dinette, saloon, cockpit, and swim deck.

Engineering

Engines twin 27 hp fresh water cooled diesels.

Engine starting batteries.

Electric engine stops.

Morse engine controls.

Propeller shaft with PSS shaft seals and Polly flex couplings drives 3 bladed folding propeller.

Fuel tanks with Cav fuel filters.

Engine room hatch with engine room vents.

Gun metal skin fittings and ball valves with water intake sea strainers.

Specially designed composite exhaust system.

All hoses double Stainless Steel hose clamped.

Steering Equipment

Duel steering stations; two helm chairs, two large diametre steering wheels, two steering compasses.

Cable steering system with manual emergency steering.

Engine gauges including tacos, oil pressure, water temperature, volt metre, electric start stop buttons bilge pump switches and alarms.

Deck Equipment

4 aluminium mooring cleats.

One electric self tailing mooring rope winch on each bow for easy docking.

Deck fuel and water fillers with breathers.

Triple roller self launching bow roller.

Below deck mounted electric anchor winch with gypsy.

50m of 10 mm Stainless Steel anchor chain and 20 kg plough anchor.

Salt water deck hose.

Fresh water hot and cold shower on aft deck.

Rails and Life Lines

Stauntions posts 600mm high solid polished Stainless Steel tube

Polished stainless steel stauntion wires.

Numerous Stainless Steel hand rails strategically located throughout the yacht.

Windows Hatches and Doors

Windows are toughened glass, tinted Grey or black.

Two forward opening hatches forward in mainsaloon.

One 600mm x 600mm opening hatch over each head, aft cabin, and two over the saloon.

Composite main entrance door with press button combination lock.

4 opening ports per hull.

Two aluminium framed sliding windows in aft bulkhead.

Plumbing

All plumbing to Australian Standards.

Polybutylene fresh water hoses and joiners.

4 electric bilge pumps one each cabin and one each engine room.

Two high volume fresh water pumps with accumulators.

All taps and shower roses.

Gas instant hot water system.

One 9kg gas bottle in locker.

Heads

Electric pump toilet.

G.R.P sink colour of your choice.

Single mixer tap set.

Single mixer shower set.

Shower pump sump kit fitted and plumbed.

Holding tanks fitted and plumbed.

Shower sump pumps.

About the designer and builder

Hi my name is Wayne Hill, I would like to take this opportunity to introduce myself with a brief personal history.

My grandparents owned and operated sailing and power boats in Moreton Bay. My father, an engineer, who sailed Moth dinghies, was Queensland champion on numerous occasions. He developed new design and construction techniques for the Moth dinghies.

Sailing was the family sport, so naturally I became involved with boats at a very young age. From the age of 6 I was fiercely competitive, sailing Sabot dinghies and competing in numerous state and national championships. I progressed into the Cadet dinghy at R.B.Y.C in Melbourne, where I spent my teenage years sailing.

The natural progression was into larger ocean racing monohulls, in which I competed in numerous races in Port Philip Bay and Bass Strait.

I was fortunate enough to have an uncle living in Queensland, who was an incredibly competitive trimaran racer. One trip up the Queensland coast on a Crowther trimaran convinced me that multihulls were the future of yachting.

I commenced as an apprentice boatbuilder in Brisbane and raced multihulls as crew competitively on Moreton Bay and the East Coast of Australia, winning numerous races including the Brisbane to Gladstone classic.

The company I was apprenticed too specialised in the construction of large Crowther designed ocean voyaging catamarans. These yachts were technically advanced - being constructed of polyester resin, fibreglass with foam core. One of these yachts has circumnavigated the world, the others have cruised extensively.

During my apprenticeship I completed a Yacht Design course, which prepared me to start my own yacht design, construction and repair business immediately on completion of my apprenticeship.

In 1985 I commenced operations designing and building Foam Fiberglass sandwich sailing catamarans for the world cruising market.

In my spare time I designed and constructed a 12 metre catamaran called Mangrove Charlie with my then partner Dorothy. We were considered one of the longest permanent live-aboard cruising couples sailing a multihull in Queensland. We cruised the Queensland coast extensively together from 1991 to 2003.

This extensive cruising provides unparalleled research into how people use their cruising yachts, and what is required to make a successful cruising yacht.

l have built or helped build many cruising multihull yachts, undertaken numerous major refits / structural repairs and redesigned or extended many hulls from various designers. There are many yachts built or being built to my design.

My designs are based on two compound curved panels, the hull canoe body and the cabin top, the rest of the catamaran is developed from flat panels.

Years of custom multihull yacht design and construction, has delivered quality yachts to many happy clients, who have travelled thousands of sea miles over many years throughout the world's oceans.

This experience provides our new clients with the confidence required to invest in a quality multihull yacht.

In early 2000 we started building flat panels for other Boatbuilders who valued our light weight, full size 15m x 3.6m CNC cut composite panel manufacturing technology.

In late 2006 the fuel price rise motivated many Recreational Vehicle manufacturers to look at reducing construction weight. We worked closely with recreational vehicle manufactures industry leaders to change to advanced composites. The results were outstanding in reducing total cost of manufacture, weight loss and product quality.

l hope one day, with my knowledge and experience, l may be able to assist you.

Kindest Regards

Wayne Hill

Master Boatbuilder Registration Number 8504814

Small Ship Designer Registration Number 85181527

Recreational Ship Master's Licence Licence Number 478672

Successful cruising yachts:

We believe some cruising yachts are for sale soon after launching or after the first cruise because the layout is fundamentally incorrect for the intended use of the yacht.

Some yachts may present well in the marina, but at sea and at anchor the yachts features become unsuitable.

Successful yacht design is part Art, part Science and part Experience, when this combination is blended correctly with a quality boatbuilder the result is a truly exceptional yacht.

Comfort

- The ability to move throughout the yacht without invading other peoples personal space.

- The ease of manoeuvring and sailing single handed leaving the other people undisturbed.

- The easily driven hull that requires very little sail area to push the yacht at respectable average speeds.

- This hullshape has a gentle motion at sea which translates to less crew fatigue tiredness and arguments.

- The yacht is relatively undisturbed by wave chop which ensures you have the most comfortable night in choppy anchorages.

Food

- The layout does not crowd the yacht with unused double cabins allowing a decent sized galley.

- The large galley increases the ease of food preparation and clean up which improves the quality of onboard food.

- The amount of storage space ensures a wide variety of quality foods are easily accessible.

- The galley is well equipped with 3 burner gas stove, grill, oven, microwave, BBQ, instant hot water, breadmaker, domestic sized solar powered front opening fridge and freezer and bench space for two people to work effectively.

Luxury

- Large well ventilated staterooms located aft where it is quieter and the yachts motion is less.

- Domestic mattresses and bed linen with bunk boards under to provide mattress ventilation which prevents wet smelly mattresses, sitting head room over the bed is very important.

- Hanging locker for the essential dressy clothes and ample storage in his and hers cupboards.

- There is ample floor space to change clothes, the seat is excellent for dressing at sea and sitting to talk to the off watch crew.

- Numerous small hatches and port holes which can be safely left open at night, or in your absence without the possibility of theft.

- This yacht has a proper lounge room which doubles as excellent sea bunks which fold down forming an extra double bed for extra guests or for extremely rough weather.

Amenities

- Separate shower with curtain to prevent the whole bathroom, including your clothes and the toilet paper from being wet.

- Elevated toilet to ensure both sexes sit to use the toilet reducing the cleaning, another advantage is the great view through the window when seated which reduces seasickness.

- A 5 kg front opening washing machine in the bath room allows quicker easier laundry chores.

Efficiency

- Under motor we consume 2 litres of diesel to travel 7.5 NM at 7.5 knots so the running cost is insignificant, it costs more to run the tender.

- The yacht runs totally on renewable energy, large solar panels with a large battery bank.

- To help charge batteries, we have propellor shaft alternators enabling continuous running of the yachts compete electrical system, including desk top computer, scanner, printer, CD burner, CD player stereo, colour TV, electronic charting, 2 x 800 watt inverters, cabin lights, depth sounders and autopilot 24 hours a day and still arrive at the anchorage with fully charged batteries.

Design and construction innovation

Over the years I had assembled an innovative technical team, custom designing, building, refitting, repairing and manufacturing sailing and power multihull yachts to the highest standards of technical innovation and excellence for the most discerning clients.

Contained within this section are numerous informative articles designed to convey my design philosophy and inform the average yachts person about multihull yachts power and sail.

Numerous unique design and construction ideas have been developed, tested and proven to enhance the performance, comfort and safety of the rapidly evolving multihull yacht.

Enjoy these informative articles and imagine the possibilities of futuristic multihull yachts.

The Design of Inboard Flair

Having undertaken many main beam and hull to underwing repairs on what we considered well designed and constructed yachts, but not designed or built by us, we wanted to offer our clients a hull shape that was gentle on the multihull structure.

We focussed our design effort on dramatically reducing concentrated loads on the beams, reducing wave pressure in the area around the hull to underwing joint and reducing underwing slamming.

Numerous main beam models were tested to destruction, the strongest beam had a 45 degree gusset from the waterline to the underwing. We had to develop a hull shape that incorporated a 45 deg gussett.

We constructed 2 identical multihull yacht models 1000 mm long 580 mm wide. We also designed and constructed an extremely deep V monohull model, this hullshape being capable of high speed with a smooth motion in rough offshore waters. This mono hull model was split in half down the centre line and the port half was fitted and glued to the starboard inboard multihull model hull and the starboard half was fitted and glued to the port inboard multihull model hull. We now had a multihull model that incorporated an inboard flair.

When the two multihull models, one with the inboard flair and one with a conventional hull shape were placed in waves with a motion comfort metre (a bowl of water), the results were amazing. At all speeds and wave angles the hull with the inboard flair had more water in the bowl after the test, indicating less motion.

The flow of waves under the underwing and around the models were carefully studied. Less waves seemed to impact on the underwing of the model with the inboard flare.

The models were then drag tested. A bridal off the bows was tied to a spreader bar to separate the models. The tow line with a short bridal was attached to the middle of the spreader bar and then towed in waves beside a dinghy. The model with the inboard flare was always ahead indicating less drag. The question is how much less?

The tow line was moved away from the hull with the inboard flair, until both models were in line while being towed, indicating equal drag and a strain gauge (fishing scales) were added to the tow line. The exact percentage less drag on the model with the inboard flair was calculated for different wave angles.

The models were then tested for their ultimate stability, they were thrown into beach surf. The models were then tested for stiffness, then destruction tested. The flared model was stiffer and stronger.

Results

The advantages of the inboard 45 deg flare starting at the bow and ending at the aft beam and on the light ship waterline are:

A stronger lighter beam structure.

A stiffer overall yacht.

Less underwing impact.

Less motion at sea.

Less leeway due to asymmetric hull above static waterline.

The leeward hull has more reserve buoyancy.

Less spray on deck.

The yacht with the inboard flair has more internal volume.

Easier assess to hull from bridge deck and best of all is faster.

Testing undertaken by me in 1985.

Recent computer modelling indicates that if the total mass of the yacht was placed on one hull it would have less drag than if spread evenly on two hulls.

A 12m full bridge deck cruising yacht was designed and built with inboard flares and tested extensively, the results were very impressive. We believe the development of the inboard flare by me is the biggest design development in recent multihull history.

Stabilizing Rudder Foils

Introduction

The motion of yachts at sea and anchor is the main reason some people don't enjoy yachting.

Multihull yachts generally have a gentle motion in a seaway, however the demands by yacht owners to reduce a yacht's motion is ever present.

Our yachts don't suffer from violent motion, you will not be flung from the toilet with your pants around your ankles, you can cook poached eggs in a fry pan while sailing and at anchor your glass of wine will not spill when a power boat steams past.

We constantly aim to reduced our yachts motion, at sea or at anchor, to ensure our clients yachting experiences are comfortable, safe and enjoyable.

The Concept

We have developed our underwater hull shape and our unique inboard flair to produce excellent seakindliness, however the desire to slow the pitching, rolling, heave and surge motion of our yachts further, led us to the development of the Stabilizing Rudder Foil.

Originally small winglets were designed for the rudders to act as endplates which allows the 20 % reduction in rudder area with the same turning power as the full size rudder. This idea rapidly developed into large endplates which should also behave as stabilizing foils to reduce the yachts pitch and roll motion.

We needed to test the theory and also determine if yachts fitted with stabilizing foils were safe for offshore voyaging.

Test 1 Delta Wing Rudder Foils

Stabilizing Rudder Foils 750 mm long 550 mm wide and 40 mm thick were designed and fitted to the bottom of 750 mm deep rudders. These foiled rudders were fitted to a new 12 metre sailing multihull.

The results proved very interesting, with a gentle motion and no stern squatting or lifting observed.

We know these foils worked well because one rudder was removed and with one foiled rudder the motion was noticeable different.

These Stabilizing Rudder Foils were extensively tested over thousands of sea miles in varied conditions for 12 months with no adverse effects noted. The design concept was correct, the next stage was further design refinement.

Test 2 Smaller Thinner Delta Wing Rudder Foils

New Delta Wing Foils were designed to replace the original foils. These new foils were placed higher on the rudders to assist boarding the yacht after swimming and to reduce the possibility of accidental damage from grounding, they were located approximately 500 mm below the waterline.

Thinner foils were used to further reduce drag. The foils were also placed further aft on the rudders.

These foils worked but they were not as successful as the original foils for these reasons:

They were to small in area and not long enough.

They were not positioned below the lowest point on the hull, so they could operate in clean water.

They were too close to the yachts hull and the water flows interacted adversely.

These rudder foils were extensively tested over thousands of sea miles in varied conditions and were replaced after 24 months.

Test 3 Propulsion Flipper Foils

Thinner larger foils 1200 mm long 700 mm wide with the trailing 400 mm flexible and with a profile shape similar to a cod fish tail, these foils acted like giant flippers.

They worked surprisingly well to windward in sloppy seas and when reaching in a beam sea at high speed 10-15 knots. They were proving quit successful, despite the extra wetted surface area.

These foils worked well at reducing motion and increasing average speeds.

However these foils had a problematic design error, while at anchor with no wind and a slight chop they propelled the yacht ahead, causing the yacht to override the anchor, quit an amazing sight in a crowded anchorage.

These rudder foils were extensively tested over thousands of sea miles in varied conditions and were replaced after 36 months.

Test 4 Large Thinner Delta Wing Rudder Foils

Large 800 mm long 600 mm wide 15 mm thin Delta Wing Foils were designed and fitted. These form a large stiff non flexible endplate and stabilizing foil, fitted 600 mm below the water line and parallel to it.

These foils give the best motion comfort and highest average speeds and after 24 months of extensive sea trials over thousands of sea miles in varied conditions these foils have proven successful!

Test Results of the Stabilizing Rudder Foils

Reduced pitching motion which provides a faster smoother ride.

Effective endplate for excellent rudder thrust for turning, from a reduced rudder draft / area.

Easy transition from displacement speeds to surfing in a following sea.

Reduced transom squatting in a following sea.

Reducing stern squatting under motor which increases motoring hull speed.

Combines well with round bilge hullshape to reduce hull drag and pitching.

Foils provide higher average speeds through less hull drag and a stable sail platform.

The longer the longitudinal foil length the greater the stabilizing effect.

High aspect ratio foils are less effective at achieving these results.

Foils have little or no stabilizing effect at less than 5 knots yacht speed.

Foils provide permanent easy boarding access to the swimdeck.

Note:

Motion metre: Sight along the deck to Horizon and view ruler in foreground to measure pitching.

Conclusion

After eight years of extensive sea trials in a variety of sea conditions the rudder mounted stabilizing foil has proven safe, reliable and effective for reducing the motion and increasing the average speed of cruising sailing Multihulls up to sustained yacht speeds of 18 knots.

Future Trends

The Stabilizing Propulsion Foil for Sailing Multihull Yachts needs further development and they will be redesigned with improvements soon.

Power Multihull Stabilizing Foils

We have developed Stabilizing Rudder Foils for Displacement Power Multihulls to improve motion comfort, trim and fuel efficiency.

We have also developed small forward, inboard mounted, horizontal foils with automatic motion control.

They feature power trim up for a following sea and power trim down for reduced pitching in a head sea.

These four foils in combination with an excellent hull shape will provide exceptional motion comfort at sea or at anchor aboard our Power Multihull Yachts.

Custom Designed Stabilizing Rudder Foils

Now Available for Your Yacht.

Uniquely designed, high-technology epoxy construction, manufactured to fit your existing rudder.

Increase your yachting enjoyment, fit these stabilizing foils to your rudders.

Raked Cutter Rig

History.

Ever since 1851 when the Schooner America with her 11.5 degree mast rake won the America's cup, mast rake has been used to improve the performance of sail power as a propulsion method. Every high speed craft including land yachts, ice boats, windsurfers and racing Multihulls use mast rake to improve performance.

Yachts that race to a handicap don't use mast rake because it is penalized by the handicap rules. In handicap racing the fastest yacht is not the winner, the yacht that sails closest to her handicap is the winner. Our yachts are not designed to any racing rules they are designed to be safe, efficient and comfortable.

The cutter rig has historically been the rig of choice for the monohull cruising sailor.

The Modern Raked cutter Rig.

In 1991 we proudly redeveloped and introduced the modern, efficient raked cutter rig into cruising Multihulls.

The Raked Cutter Rigs features:

A 7.5 degree mast rake, the key to the whole modern cutter rig working so well.

Parallel fore stays for the greatest cutter effect.

The distance between the forestays is spaced for maximum sail efficiency.

The Jib easily tacks between the stays.

Low aspect ratio rig to increase stability, reduce rig loads and reduce pitching.

Low centre of gravity, low wind resistance cruising rig.

The stay sail is close to the deck which improves efficiency and pressurizes the windward nets and lifts the leeward nets reducing on board spray and increases stability.

With the roller furling Jib on the composite bowsprit, which is wide enough to walk on and the fully battened stay sail on the fore beam, the fore triangle is broken into two easily handled sails.

The large fully battened mainsail is reduced in area by the mast rake.

This long low sail plan increases stability, reduces the sail handling effort required by the crew and off the wind increases the power to propel the yacht.

Notes

This rig is the complete opposite approach to the trend for high aspect ratio fractional rigs being installed on cruising yachts.

We have observed the trend by designers and builders to increase the height of masts to "improve performance" however we are informed by boat owners that increased speeds are achieved by reefing the mainsail. This is not surprising, tall masts raise the centre of effort of the sailplan, this increases the heeling force which pushes the leeward hull further into the water increasing hull drag. If you look into the hull shapes, for example a 12 m catamaran with fat hulls 1.2 to 1.4 m wide on the water line and fixed keels, the drag on these hulls when the leeward hull is depressed increases considerably. This type of hullshape is happy with both hulls evenly floating while motoring or sailing down wind not being pressed hard to windward or reaching.

The high aspect ratio racing rig works exceptionally well on racing yachts however it does not make slow hull shapes fast hull shapes.

How does mast rake increase yacht speed?

The more horizontal the fore stay angle the greater the vertical lift generated by the jib. Effectively lifting the bows which reduces the yachts displacement which reduces wave drag and increases the yachts speed. Raking the mast aft has a similar effect to fore stay angle.

With a vertical mast the forces generated by the mainsail are forward and downwards but by raking the mast aft these forces are rotated to become forward and upward resulting in increased speed due to decreased displacement.

The effect of mast rake is apparent sailing to windward but far more obvious when reaching and running.

Because the bows are not driven down by sail pressure we can use finer bows which further reduce drag and pitching.

Another advantage of mast rake is reduced pitching caused by the lack of the pendulum effect.

With a vertical mast in a sea way the masts mass and momentum forces the bows and sterns up and down alternately greatly increasing the pitching.

With a raked mast in a sea the masts mass and momentum forces are rotated to force the bows forward and the sterns up and down alternately greatly reducing the pitching.

The combined effect of the lift generated from the raked cutter rig, the lift generated from the under wing, the extra buoyancy and dynamic lift generated by the inboard flair and the stabilizing effect of the rudder mounted foil combine to reduce heeling, under wing wave impacts, yacht motion and increases average speeds.

The Raked Cutter Rig of Mangrove Charlie has proved to achieve higher average speeds than any other rig aboard a liveaboard cruising Multihull yacht yet encountered.

Test results

Test have been undertaken on many yachts over many years but the most convincing test was aboard a 2000 kg 10 metre racing Multihull with a 15 metre rotating mast. This yacht started life with a vertical mast, and over two years the mast was raked progressively aft with consistently improving performance. The lift generated by the raked mast allowed us to carry more sail area in stronger winds off the wind and when sailing to windward, the crew of four would sit forward of the mast to keep the bows down.

On a 1.5m long radio controlled test model trimaran the mast was raked so far aft that the model capsized bow over stern from the lift generated from mast rake!

Note: We were testing the feasibility of using surface effect wings for racing trimaran beams at the time and these foils may have contributed in the capsizes [tested in 1981]

Conclusion

Our theoretical calculations and practical testing indicate that the raked cutter rig on the Mangrove Charlie generates 240 kg of vertical lift in 18 knots of apparent wind and sailing to windward at 8 knots this reduction in displacement equates to approximately 0.1 knots extra yacht speed! The lift generated by the raked cutter rig increases as the sheets are eased which increases the improvements in downwind yacht speeds.

Sailing Multihull Speed

The average mileage actually travelled over a 24 hour period at sea in a 20-25 knot trade wind for 12m Multihull Yachts

Pure Racing Multihull 300 + NM

Racer/Cruiser Multihull - no fixed cruising equipment 250 NM

Cruising Multihull - fractional rig and centreboard 230 NM

Cruising Multihull - mast head rig or keels 220 NM

Cruising Multihull - fully equipped, live aboard, husband and wife sailing team 200 NM

NOTE.

Yacht designs differ considerably in their speed potential, comfort and safety. The yacht's hull shape being the most important variable. The above table does not include poor design. Higher averages will be achieved over a shorter time span and in smoother water. All yachts were fully crewed and in racing trim. As the wind decreases the speed difference between a racing multihull and a cruising multihull increases considerably.

When buying a multihull, if anyone claims that their yacht achieves unusually high speeds, have it written into the contract of sale that these speeds must be achieved and maintained during sea trials.

You will be surprised how quickly salespersons will back paddle when confronted with this request.

Unfortunately this is the only way to stop some salespeople from claiming that short, fat, heavy multihulls with keels can achieve speeds faster than a stripped out racing multihull.

Sailing Multihull Stability

Quite often we encounter multihull yacht owners who have no idea how much sail they can safely set and consequently they cruise along quite slowly.

We calculate stability numbers for all our Multihull Yachts. These numbers are for sideways stability and all our yachts are more stable fore and aft than sideways.

We have found with our hull shapes, the faster you sail, the smoother the ride. So set whatever sails are required to achieve the desired speed, engage the autopilot and enjoy the exhilarating ride

Mangrove Charlie Stability Numbers

Apparent wind speed windward hull starts to fly with wind abeam and sails sheeted hard, yacht not moving and light ship weight.

| Sail combinations | Wind speed |

| Full main and spinnaker 1 reef and spinnaker 2 reefs and spinnaker Spinnaker |

25 Knots 27 Knots 28 Knots 32 Knots |

| Full main genoa and staysail Full main and Genoa Full main and staysail Full main |

30 Knots 32.5 Knots 37 Knots 42 Knots |

| 1 reef and Genoa I reef and staysail 1 reef in mainsail |

35 Knots 42 Knots 47 Knots |

| 2 reefs and staysail 2 reefs in mainsail Staysail Bare poles |

46.5 Knots 52.5 Knots 93.5 Knots 138 Knots |

When sailing short handed at sea, restrict yacht speed to:

| Sailing to windward >40 deg Apparent Apparent wind forward of the beam Apparent wind aft of the beam |

9 Knots 12 Knots 15 Knots |

You can quite safely set whatever sails are required to achieve these speeds.

Note:

- 15 Knots = 360 NM per Day!

- 15 Knots = 27.80 Km / hour!

- 15 Knots = 7.72 M / second!

At 15 knots this yacht physically moves 50,000 Litres of water per second!

The captain is responsible to ensure that the sail combinations do not exceed the wind speed or boat speed specified.

Daggerboards or Keels

Daggerboards are the logical choice for the cruising sailor.

The best anchorages

The shallow draft, less than one metre, from a retracted daggerboard enables anchoring in the premium position close to beach in the shallow smooth water, enabling swimming from the swim deck and short dinghy trips to the beach.

Maximum efficiency

Daggerboards produce the maximum lift for the least amount of drag, allowing the yacht to sail to windward at high speed with the minimum amount of leeway. Daggerboards are only fully down when sailing to windward in winds less than 15 knots. They are slightly retracted when reaching to reduce drag and increasing speed. When running down wind or motoring they are fully retracted reducing parasitic drag even more. Forward raked daggerboards reduced tip vortices make the yacht directionally unstable when down so the yacht sails responsively to windward. Self tacking daggerboards automatically adjust to the new tack, maximizing efficiency and allowing the yacht to sail with the minimum amount of leeway. This is easily achieved by making the trailing edge of the daggerboard tight in the case and allowing the front of the daggerboard to move three degrees every time the yacht changes tack. The cord length of the daggerboard should be equal to the maximum beam of the hull. The beam to length ratio of the daggerboards should be the same as the hull. Their area should be 1% of the working sail area.

Safety

Daggerboards can be retracted if the bottom is touched allowing the yacht to find deeper water, a very important safety feature. In rough conditions they are retracted to allow the yacht to slip sideways when large waves impact on the hull, reducing the probability of structural damage.

Balance

When sailing to windward or reaching you can balance the yacht by adjusting the lateral resistance. This is easily achieved by raising or lowering the windward or leeward daggerboard which enables finger tip helming, less wear on the autopilot and increased speed.

Running aground

Forward raked daggerboards retract when grounding, slide easily in the Daggerboard case and don’t rattle.

Fixed keels do not allow multihull yacht owners to take full advantage of the multihull concept because their draft is excessive.

Safety

The ultimate safety of the keeled yacht is reduced because the yacht cannot slip sideways quickly in rough water causing structural damage and reduced ultimate stability.

Grounding

Once a keeled multihull yacht is grounded, it is almost impossible to refloat if there is wave action, because the keeled hull will lift with each wave action and ground the yacht further up the beach, leaving the yacht little chance of refloating without assistance and the yacht will suffer more structural damage because waves are larger and more powerful in deeper water.

Poor Performance

Multihulls with fixed keels have sailing ability that has been severely compromised. They sail relatively slowly because of the increased drag of the keel and the extra drag of hull sliding sideways. They point as close to the wind but they slide sideways, causing tacking angles of 110-120 degrees in moderate winds.

Conclusion

Keeled multihulls are fine for the many people who want a motor sailer, however they should not be described as performance multihull sailing yachts, regardless of how fast they look. They are well suited to motor sailing and the charter yacht industry, where their speed is restricted to less than 10 knots by law.

Hull Shape

Our cruising multihulls are easily driven. They achieve high average speeds with a relatively small sail area or they achieve high top speed under full sail.

On an ocean or coastal cruise the number of miles travelled per day is far more important than the top momentary speed recorded each day.

Water Flow

Our hull shapes, with their deep forefoot cut the water forward and allow the water to flow around the hull to the semicircular transoms. They do not force the water to change direction to flow under a flat transom.

By designing the water to flow around the hull the hull drag steadily increases as the yacht's speed increases. The result is a cruising speed range of within a few knots of the average speed.

Semicircular or Flat transoms

Hulls with large wide flat transoms are the worst type for the cruising sailor.

Large wide flat transoms cause increased drag at lower speed and less drag at higher speeds. A cruising multihull with a wide flat transom can (on a windy day with lots of sail up) surf down the face of an ocean swell at speeds in excess of 20 knots then slam into the back of the wave in front and rapidly decelerate to 6 knots then surf off down the wave face again. This is fun on short day sails or while racing but for the cruiser this sensation becomes quite unnerving.

If yachts with large wide flat transoms reduce sail to stop surfing the additional low speed hull drag causes them to sail at slow speeds. These hull shapes on a cruising catamaran have a slower average speed than our hull shapes because they surf for only a few seconds.

The hull drag of wide flat transoms do not steadily increase with hull speed so they suffer large variations in speed. Large variations in speed cause large changes in the apparent wind which requires sail trimming or course changing to prevent the sails stalling. Auto pilots do not perform as well on multihulls with wide flat transoms.

Large wide flat transoms can be dangerous for sailing multihulls. When the yacht is sailed hard and the lee hull is depressed causing the centre of floatation of the leeward hull to move aft, which causes the boat to sail bow down, which reduces stability.

Large wide flat transoms work exceptional well for the racing yacht. Racing yachts are lighter and more easily driven. The crew constantly trims the sails to adjust for the ever changing apparent wind. They are able to maintain the high speeds where the large wide flat transom provides its low drag advantage.

Layout Design Notes

Designing Yacht accommodation layouts is not like designing a house. In house design you can place any room anywhere and the house will not sink, lean over or suffer structural failure.

When designing a yacht the positioning of the weights and the amount of weight a yacht can carry is critical. Incorrect weight or wrong weight distribution causes the yacht to float out of trim (bow or stern down) and not to the designed waterline (over weight).

Dangers of over weight and out of trim multihulls.

- Capsize from reduced stability.

- Poor sailing / motoring performance from extra hull drag.

- Structural failure from excess weight.

- Reduced resale value

Painting the water line where she floats is dangerous and represents poor yacht design and construction.

Custom or Production

The cost of a custom multihull is very competitive with an Australian production multihull. If you contracted us to design and construct an exact copy (size, shape, finish, building materials, build quality, equipment specifications) of a production multihull the cost would be very similar. This may seem surprising, but we do not have the cost overheads of production multihull construction.

Cost overheads of a production Multihull.

- Designer royalties.

Usually half the cost of custom plans. - Mould construction.

To build a female mould you must first custom design and build a plug boat. The female mould requires approximately five times the fibreglass as the finished moulded boat or distortion in the finished moulded boat occurs. - Complicated design.

The shape of the finished yacht must be able to be withdrawn from the female mould. To improve the hull shape or deck styling a new mould must be manufactured - High overhead factory.

Not always used to maximum capacity. - Tools and equipment often not fully utilized.

- Continuous print advertising.

- Colour brouchers

- Boat show exhibitions.

- Sales representative's salaries.

- Dealer commissions / brokers fees.

- Demonstration yacht.

If a production multihull requires modifications to meet your specifications then it would be cheaper to contact us and have a new yacht designed and constructed. Our custom multihulls built with our unique building method are lighter, stronger and faster than Australian production Multihulls.

Of note over time production multihull builders have moved overseas, any that remain in Australia use imported materials and equipment as Australia manufactures very little anymore.

The Cost of Multihull Maintenance.

Maintenance costs vary little within a size range of similar multihulls. The cost of maintaining a 10.5 metre cruising multihull compared to a 12 metre cruising multihull with exactly the same accommodation layout (number of cabins, heads.) and the same equipment will be very very similar.

The maintenance cost is on the yachts equipment (stove, toilet, upholstery, carpet, halyards, electronics, electric's, water pumps, refrigeration, anchoring and mooring equipment ) not on the total yacht.

The yachts equipment lasts approximately 10 years depending on Quality, installation and use. The yearly cost to keep your yacht appearing and working like new is 10% of the value of the yachts equipment. The high maintenance yachts equipment represents a small percentage of the yachts total value. A well designed, built and maintained Multihull would be expected to last at least 50 years.

Marina and slipping fees are slightly more for the longer waterline but the cost of anti-fouling, anodes, propeller maintenance and repairs to hull dents and scratches is very very similar.

The initial cost of the longer yacht is more, but the ongoing maintenance cost is similar to a shorter yacht with the same accommodation layout and equipment.

Don't be put off by the perceived extra maintenance cost of a longer waterline, perception is not necessarily reality. The advantages of longer waterline over the shorter tubby hull at sea, at anchor or in harbour is enormous. The extra money invested on waterline length will be appreciated with more enjoyable boating and greater resale value.

Multihull Pitching

Multihulls generally have a much more acceptable motion to most people than monohulls. Monohulls both power and sail pitch further than a comparable multihull. With my hull design the aim is to reduced the yachts motion, at sea or at anchor, to ensure our clients yachting experiences are comfortable, safe and enjoyable.

What causes pitching?

The centre of buoyancy is directly over the centre of floatation.

Moving the hulls centre of floatation aft and keeping the centre of buoyancy around amidships will help dampen pitching. The further the distance between the centre of floatation and the centre of buoyancy the less the boat will pitch. But too much and the motion becomes short and fast!

The centre of gravity is too high.

The mast is too tall or too heavy.

Too much equipment is stored high in the hulls or bridge deck.

The underwing is too high above the waterline.

The underwing extends too far forward or too far aft.

The ideal underwing length is the same as the overall beam of the boat which will result in a “square” underwing plan. In reality the accommodation plan is kept square with the cockpit placed aft.

Increasing the underwing length will increase the amount the boat pitches.

Excess weight is placed in the forward and aft ends of the boat. Concentrating all onboard equipment amidships will result in a short fast motion.

Placing onboard equipment towards the ends will result in longer slower motion.

Hull prismatic coefficient too low or too high.

Bulbous bows and or transom extensions may reduce pitching.

Yacht floating below designed waterline and overloaded.

Remove excess weight.

Excess hull drag caused by poor hull design, keels, unfair hull or excess marine growth on the hulls.

Local wave conditions not suited to your size of yacht.

If you have a multihull that you believe pitches excessively, study the data I have provided and work with onboard weights to achieve a better outcome. Rudder foils may help your pitching while sailing.

Purchasing a new or preowned yacht can become confusing and frustrating, with information overload a real possibility. There are so many types and styles of cruising multihulls on the market, with apparently similar yachts having considerable price differences.

If the search for the dream ship is turning into a confusing nightmare send us an email and we will try to help.

Well done your finished, Hopefully you understand a little more about the design philosophy and construction methods of Mangrove Charlie.

Thanks

Kindest Regards

Wayne hill

mangrovecharlie.com